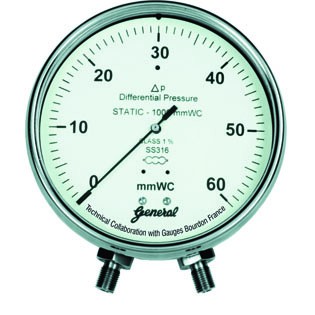

Differential Pressure Gauges Bellow Type

DPBL / LFDBPL / SFDPBL / LSDPBL

Features

Bellow type construction

Reference Standard: EN - 837

All SS internals

Chemical seal unit (optional) for process suitability

Accuracy ±1% FSD

A set of two stainless steel bellows mounted on a force balance enables direct reading of the actual differential pressure

Each Bellow of the pressure Gauge can withstand the full static pressure without any damage or shifting being caused to the instrument

72032.jpg)